Heavy carpentry

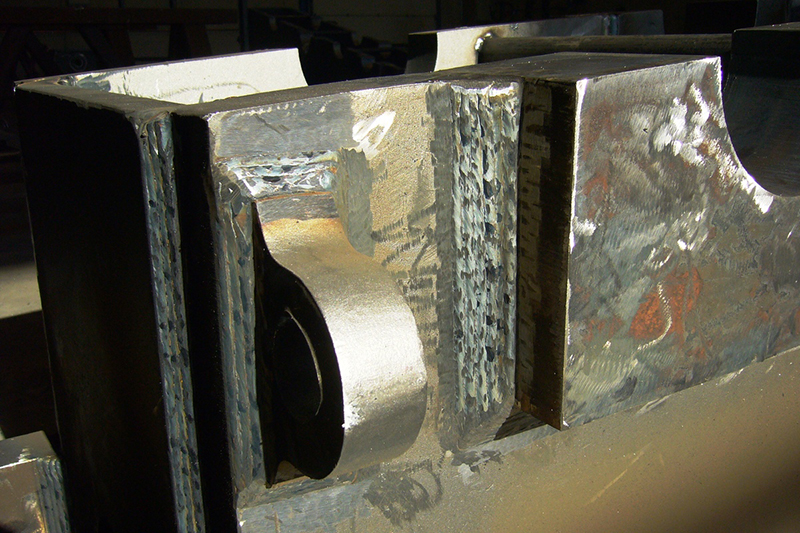

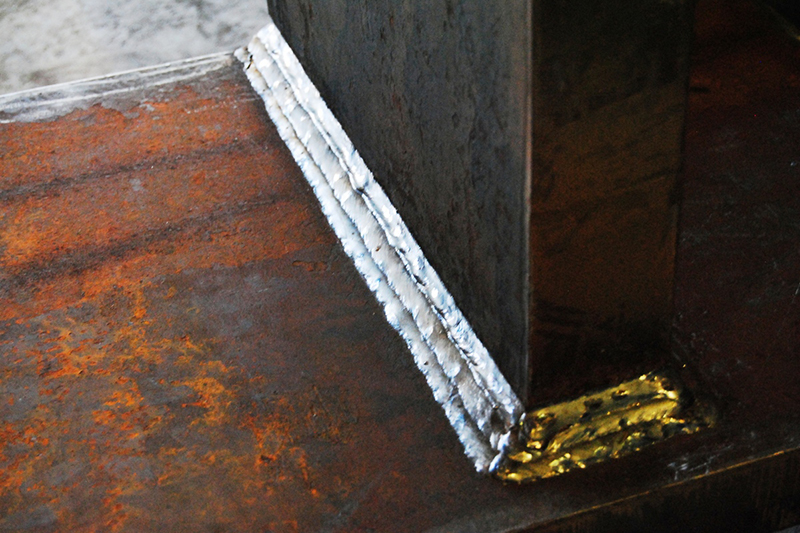

The Heavy Carpentry division employs a pantograph oxy-cutting machine capable of processing sheet metal ranging from 5 mm to 300 mm in thickness, and up to 16,000 mm in length, equipped with state-of-the-art CNC technology. These capabilities grant New Port a national exclusive in this type of treatment.

Equipped with top-tier machinery such as saws, rolling machines (up to 25 mm), shears, and assembly and welding stations capable of developing components weighing up to 20,000 kg, the facility (featuring two cranes of up to 20 tons each) can rapidly manufacture parts for various types of industrial machinery and civil structures.

Light Carpentry

The Light Metal Carpentry division is equipped with a plasma cutting machine measuring 2500mm x 16000mm, capable of handling thicknesses up to 25 mm with CNC, along with a “Fiber” Laser machine measuring 1,500 x 4,000 mm, featuring tube cutting options. Through dedicated programs, it performs cuts, profiles nesting, and special shapes of all kinds.

The department can also provide corrugated sheets and other non-ferrous materials. The production process is supported by a technical office equipped with CAD systems and qualified personnel currently fluent in three different languages: Romanian, Russian, and Italian.

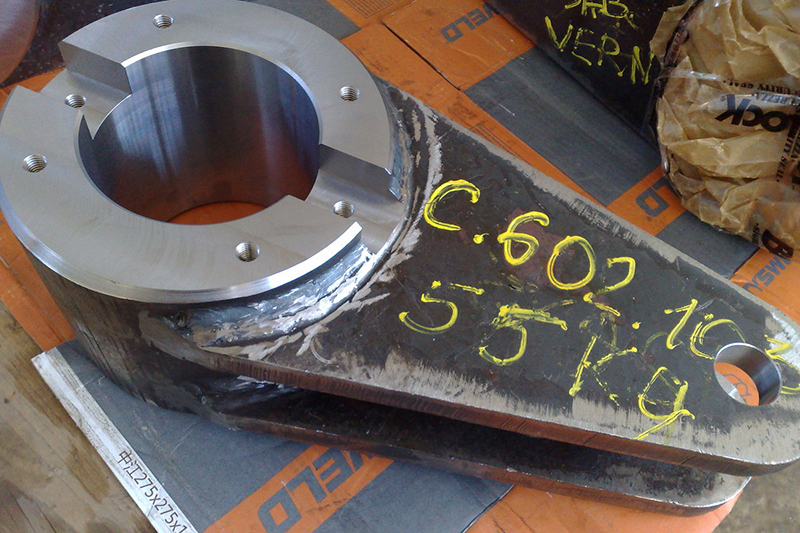

Precision Components

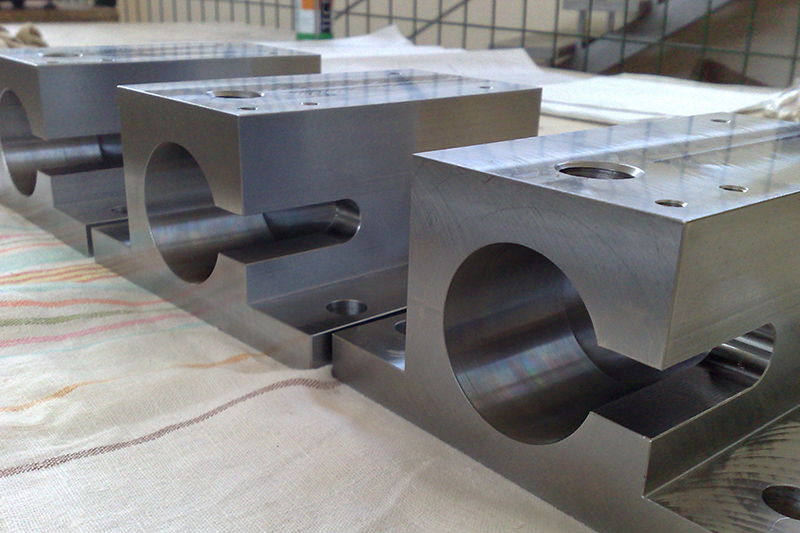

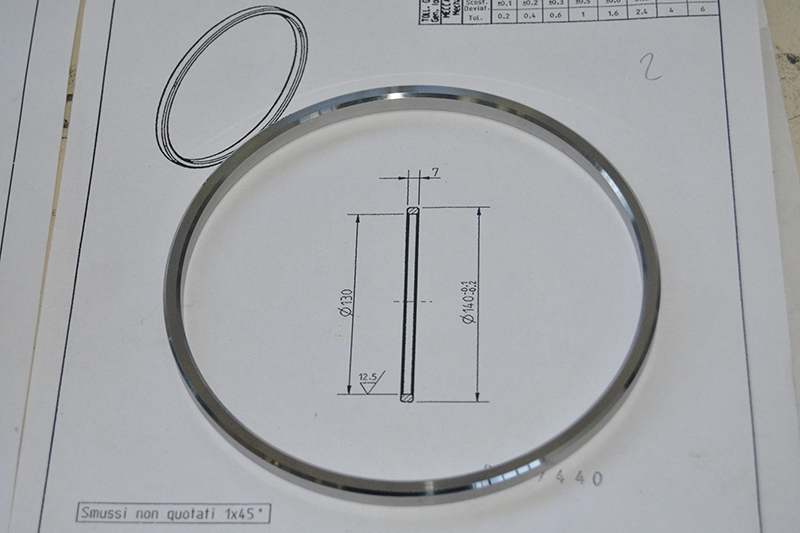

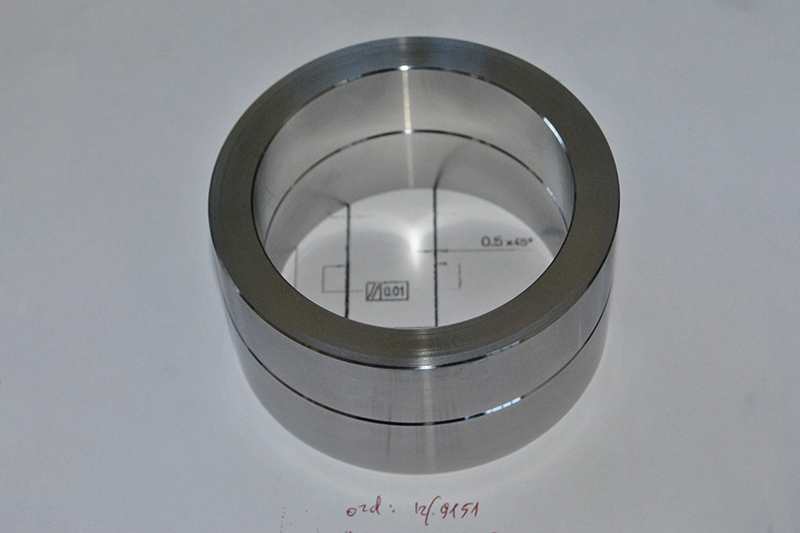

The company features a CNC machining department with various machining centers of up to 3500mm x 1000mm x 1500mm, two lathes (with a diameter of 350 mm and a table of 1300 mm), and other auxiliary machinery. These machines enable us to produce a wide range of parts with the required quality and tolerance.

The department is equipped with a presetting tool for the computer system and a dimensional control department where all pieces are inspected after completion. The CNC machine tools division is performing additional precision metal carpentry work on a medium to small scale (3500x800x1000). This includes milling, milling/boring, and turning.

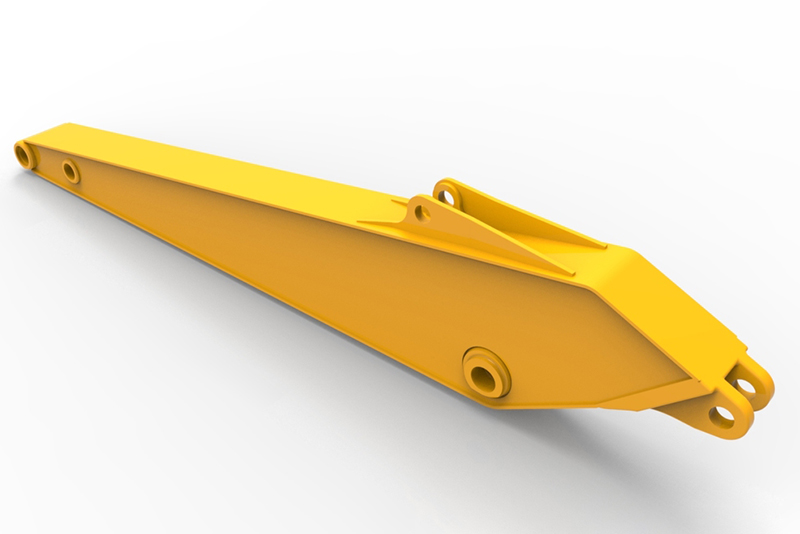

The company can provide high-quality finished products. Upon request, we can supply pre-painted pieces with primer and galvanizing. All divisions undergo quality control tests before shipment, and just-in-time delivery is ensured with weekly deliveries to Italy, Switzerland, Romania, Austria, and Germany, as well as neighboring CSI countries.